what is viscose fabric

What is viscose fabric?

Where did viscose come from? Analysis of the advantages and disadvantages of viscose fabrics

Today, viscose fabric is a popular choice for those who prioritize environmentally friendly materials. Before discussing fabrics, it's important to understand viscose fiber. Viscose fiber is a synthetic fiber that was first created in 1891 by Cross, Bevan, and Beadle. By using cotton as a raw material, they were able to produce a sodium cellulose sulfonate solution that was very thick and viscous, hence the name "viscose".

In 1893, a process was developed using acid to re-precipitate cellulose, creating what is now known as "viscose fiber". The production of viscose fiber is a complex process, and any material containing it is also referred to as viscose fiber, or alternatively, rayon or ice silk. Technological advancements have led to the creation of high-quality fiber options like Tencel and bamboo fiber.

Various natural fibers like bamboo, cotton, and wood undergo a process that turns them into soluble cellulose xanthate. This process involves alkalization, aging, and sulfonation. The resulting substance is then dissolved in diluted lye to create viscose. When sulfuric acid is added to the coagulation bath, the cellulose precipitates and regenerates. The separated cellulose is then washed, desulfurized, bleached, and dried to produce viscose fiber. Different types of viscose fibers are available based on the raw materials and spinning processes used. Common materials in the market include matte silk, modal, and artificial fur, each with unique characteristics and applications. Viscose fabric is widely used in various textile products, clothing, blankets, decorations, and more.

main features

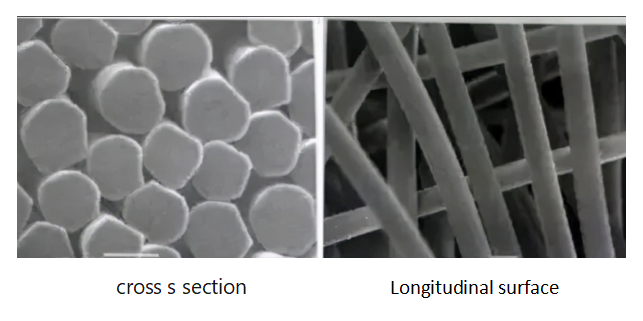

The cross-section of viscose fiber is round or random, with holes inside, and random grooves on the longitudinal surface.

Viscose fiber has better alkali resistance, but not acid resistance. Its acid and alkali resistance is worse than that of cotton fiber.

The polymerization degree of viscose fiber macromolecules is 250~500, and the crystallinity of macromolecules is lower than that of cotton fibers, generally around 30%. The system is relatively loose, making its breaking strength smaller than that of cotton fibers, which is 16~27cN/tex; The elongation rate is larger than that of cotton fiber, which is 16%~22%; its strength in wet state drops greatly, only about 50% of dry strength, and its wet state length increases by about 50%; Low, poor elastic recovery, poor dimensional stability, easy elongation of the fabric, poor wear resistance. Rich and strong fiber has greatly improved the above shortcomings of viscose fiber, especially the strength in the wet state has been greatly improved.

The structure of viscose fiber is loose, and its hygroscopic ability is higher than that of cotton, which is the fiber with the strongest hygroscopic ability in common chemical fibers. After absorbing moisture, it swells significantly, and the fabric woven with it shrinks greatly and becomes hard when it is wet.

The dyeing performance of viscose fiber is good, and the dyeing spectrum is complete.

Viscose fiber has a good heat resistance and thermal stability.

Due to the strong dilution ability of viscose fiber, the specific resistance is low, and the antistatic performance is good.

The light resistance of viscose fiber is similar to that of cotton fiber.

Advantages of viscose fabrics:

Viscose fabric is ideal for sportswear due to its excellent antistatic properties. It feels very smooth and doesn't stick to the body. It also has the highest moisture content that matches human skin's physiological needs. Additionally, it offers good air permeability and humidity control, earning it the nickname "breathing fabric". Ready-made garments made from this material have many benefits, including a soft texture, smooth and cool feel, breathability, antistatic properties, and vibrant dyeing.

Disadvantages of viscose fabrics:

Although the fabric has many advantages, some disadvantages have to be mentioned. Due to the material problem of viscose fiber, its quality is relatively heavy, so its elasticity is poor. If it is squeezed and rubbed, it will be very It is easy to wrinkle, and the recovery performance is poor, it is difficult to restore to the original; in addition, the viscose fabric is not washable, and if it is washed for a long time, it will cause hair loss, pilling, and shrinkage.

However, with the development of modern high technology and the continuous improvement of production technology, the performance of viscose fabrics has been improved step by step, and some shortcomings have gradually been overcome. Therefore, the improved viscose can have a better feel and durability, and this high-quality viscose fabric can be found in the cloth network!

Accordingly, when washing and maintaining, it should be done as follows:

1. Given its large shrinkage rate and low wet strength, it should be soaked as it is washed, and it should not be soaked for a long time. Viscose fabrics will become hard when exposed to water, so wash them lightly to prevent fluff or cracks. Use neutral detergent or low alkali detergent. The temperature of the washing liquid should not exceed 45°C. After washing, fold the clothes up, squeeze out the water, and avoid wringing. Avoid exposure to the sun after washing, and should be exposed to the sun in a cool or ventilated place. When buying fabric, it should be about 10% longer than the required amount of ordinary cotton fabric, and it should be shrunk before cutting.

2. Use thinner needles when sewing and the stitches should not be too dense.

3. It should be changed and washed frequently to prevent long-term wear and deformation. When washing, rub gently and wash lightly, avoid using force, let alone use a scrub brush to prevent fluffing. Squeeze the water after washing, do not wring it hard to prevent wrinkles; it should be soaked and washed, and wrung dry at any time. If it is soaked for a long time, its strength will be affected; because its resistance to sunlight is not good, exposure to the sun will make it fade and its strength will decrease, so it should be dried in the shade in a ventilated place, and drying with water can also reduce clothing wrinkles.

4. It is best to iron when it is half dry, and the temperature should not exceed 100 ℃. If it is already dry, you can place a damp cloth on top of the clothes for ironing, or spray some water for ironing. When ironing, push and pull less hard to make the clothes naturally expand and align; iron slowly and lightly.

5. Due to poor wear resistance, it is easy to fluff and deform, so it should be worn as little as possible and pulled less to extend its life.

6. Because it is susceptible to moisture and mold, it must be washed and dried thoroughly before storage, and then put into boxes and cabinets.